I have a 2005 Jeep Wrangler Unlimited (also known as a TJ Unlimited

or an LJ), a vehicle infamous for

a problem known as the

“Death Wobble”. This problem can affect a variety

of vehicles, but 1997 and newer Jeep Wranglers and the Jeep Cherokee

are particularly susceptible to it due to an unfortunate resonance

in the front end at typical road speeds (45–55 mph). The

Death Wobble is a violent front-end oscillation that feels like it

might shake the vehicle apart, and makes steering somewhat

difficult. There

are numerous videos

online demonstrating the problem, as well as a broad range of

explanations of what causes it and how to fix it. Since it affects

at least three models (Cherokee, TJ Wrangler, and JK Wrangler) of

vehicle, some of these explanations apply to some models and some

apply to others. This is the story of how I addressed the Death

Wobble in my Jeep. It’s something between a simple log, a

narrative, and a how-to.

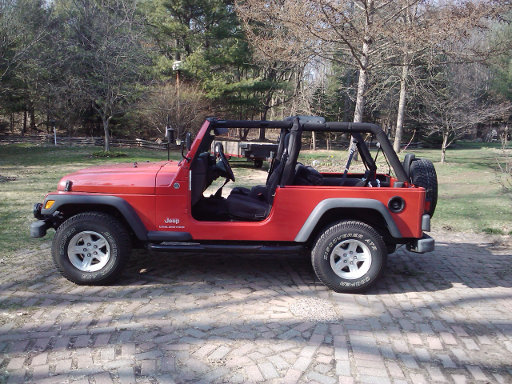

The Jeep in question, several years ago. You can’t quite see

the wobble here.

Identifying damaged parts

The most often-fingered culprits for the Death Wobble in a TJ

Wrangler seem to be:

- Worn ball joints

- Damaged or worn steering dampener

- Worn track bar end or bushing

- Worn control arm bushings

- Poor wheel balance

- Bad alignment

I have had two sets of tires on my Jeep since it developed the Death

Wobble (which, by the way, was during the warranty period, and

Chrysler claimed they’d never heard of it — despite thousands

of references to it on the Internet, videos of it in action, and my

Jeep experiencing it, which, of course, they “couldn’t

replicate”), and had it aligned twice, so I knew those weren’t

the fundamental culprit. The most likely problems in my case were

therefore ball joints or the track bar.

Getting under the Jeep to figure out what I might need to replace, I

found that the lower driver’s side ball joint could be moved with a

pry bar — not a good sign. The tie rod and drag link were

also both obviously worn out (they could easily be moved/rotated

with one hand). The track bar is not easy to check without removing

it, nor are the control arm bushings or steering dampener.

In addition to the items I could tell were worn out, the sway bar

links are often casualties of the Death Wobble, and the steering

dampener was almost certainly bad after numerous Wobbles. So I put

together a list of about $600 in front end components, and ordered

them. I purchased mostly OEM-equivalent components, not off-road

upgrades:

- Drag link assembly

- Tie rod ends

- Steering dampener

- Track bar

- Polyurethane track bar bushing

- Sway bar links

- Polyurethane sway bar bushings

- Upper and lower ball joints

- Upper and lower control arms

- Upper control arm axle bushings

Both the track bar and drag link have tie rod ends made onto the bar

itself, so they had to be replaced even though only their ends were

bad (or presumed so, in the case of the track bar). The track bar

comes with a rubber bushing pressed in place, but I bought a

polyurethane bushing to replace it. Furthermore, it took some doing

to figure out the situation for the control arms; the lower control

arm has two of the same bushing, and the upper control arm is sold

with one bushing installed and requires the front bushing to be

purchased separately, at least

from Quadratec, where I was

ordering. The lower control arm bushings can be bought separately

or with a new control arm for very little more than the cost of the

bushings, so I purchased the entire assembly.

Initial disassembly and steering linkage

When the parts started arriving, I put the Jeep up on jack stands

(near the body mounts just behind the front tires, supporting the

frame), took off the tires, and pulled apart the steering linkage.

You’re going to want to take some measurements when you do this, so

that you can get things together close enough to get to the

alignment shop (or close enough to ease alignment, if you’re doing

it yourself). Measure the distance from the end of the tie rod to

the center of the bolt (or grease zerk) on each tie rod end, as well

as the center-to-center of the two end bolts, then repeat for the

movable end of the drag link. Write this all down, it’s going to be

a while before you get to it again!

On my Jeep, all of the bolted parts came apart with comparative

ease, nothing was substantially stuck (except some cotter pins), and

nothing broke (except the aforementioned cotter pins). Your mileage

might vary, there, depending on climate, storage conditions, and

damage from off-road activity. My Jeep has lived in a garage for

most of its life and its off road activity is limited to trail rides

(no rock climbing or river fording here), so things weren’t in

terrible shape down there.

With the steering linkage off, the steering knuckles (the bit the

wheel hub mounts to) are free to rotate back and forth, making

disassembly easier, so I removed the brake calipers and rotors.

When you remove the calipers, set something by the frame to support

them; I used some buckets and boards. They shouldn’t put tension on

their brake lines, and they’re going to be there for some time.

At this point I had to go buy my first “oops” part

— a 1/2"/13 mm spline socket for the wheel hub

bolts. They’re either 12 point or spline, but the spline socket

worked great. Fortunately a friend had the 36mm axle nut socket, so

I didn’t have to buy that. Once I had the tools, I got the wheel

hubs off without difficulty. Miraculously those spline bolts were

not siezed (they looked terrible), and came right out.

siezed, and the

At this point the narrative order gets a bit muddied; I definitely

took the passenger side wheel hub off one day and the driver’s side

wheel hub off the next day, but I don’t remember what (if anything)

I removed in between. I think nothing. Either way, it turned out

that a) both wheel hub bearing seals were leaking, so I

needed two new wheel hubs (it’s a sealed, non-repairable unit, about

$63 each); and b) no local parts store had two wheel hubs.

I bought one each at two different stores and called it good.

Ball joints, sway bar, and reassembly of steering

With the wheel hubs off, the U-joints and half axles literally pull

right out. My U-joints seemed to be in good shape, so I just set

those aside. This leaves the steering knuckle mounted on the ball

joints and ready to be removed by removing the ball joint castle

nuts. A few swift raps with a 3 lbs drilling hammer (the best

hammer ever: Estwing

B3-3LB Drilling Hammer ) knocked each knuckle off the

ball joint tapers. At this point the ball joints can be inspected

properly; both of my lower ball joints were completely destroyed,

and flopped around in their housings like a ball-in-socket. The

upper ball joints were still pretty stiff, but I elected to replace

them anyway. The amount of play in the lower ball joints when

prying them with the frame lifted but everything assembled versus

the amount of play in the disassembled joint was shockingly (to me)

misleading; I would not have guessed they were so bad, from the

assembled movement.

) knocked each knuckle off the

ball joint tapers. At this point the ball joints can be inspected

properly; both of my lower ball joints were completely destroyed,

and flopped around in their housings like a ball-in-socket. The

upper ball joints were still pretty stiff, but I elected to replace

them anyway. The amount of play in the lower ball joints when

prying them with the frame lifted but everything assembled versus

the amount of play in the disassembled joint was shockingly (to me)

misleading; I would not have guessed they were so bad, from the

assembled movement.

Removing the ball joints with a rented ball joint press was somewhat

complicated, as the receiver rings supplied with the press were not

quite appropriate sizes and the press was not deep enough to place a

ring on both sides of the bracket (which would have been required

for replacement of the lower ball joint and both removal and

replacement of the upper). This required some jury-rigging. The

lower ball joints were relatively easy to push out, except that the

press had to be mounted a bit crooked. The upper ball joints I then

pushed out by the stud; the passenger side ball joint separated (and

the stud came out entirely) by this method, allowing me to push

directly on the ball joint body without a ring. The driver side

joint pushed out by the stud!

Replacing the ball joints was more difficult than removing them, for

the same reasons. We put the lower ball joints in first, which may

have been a mistake; it’s not clear which order would have been

easier. They could be pushed most of the way in without a receiving

ring on the back, which allowed enough throat in the press to put a

large socket on the back to receive them. The press plates and

rings would not have fit. The upper ball joints took a lot of

head-scratching and fiddling, but ultimately we were able to get

them in by placing the smallest ring available for the press

directly on one side of the press (which was OD sized almost exactly

the same as the ID of the ring, so separating them after the fact

was rather … enjoyable), saving the depth of an end plate,

and shimming the other side with a piece of metal plate and a

screwdriver tip to get everything straight. It took four hands.

Installing the ball joints was the second most difficult part of the

whole job; it took maybe two or two and a half hours. Once they

were in, re-installing the (cleaned, primed, and painted) steering

knuckle was easy. Before re-installing the steering linkage,

however, it seemed prudent to do the sway bar links and sway bar

bushings; both were trivial. My only note here is that I couldn’t

find any torque numbers for the poly sway bar links; a call to the

manufacturer (Crown) confirmed that they require OEM torque

(70 ft-lbs for the lower bushing and 40 ft-lbs for the

upper joint). The steering linkage was not difficult. The steering

dampener did require rocking the wheel back and forth a bit, as the

bolt (installed to the drag link) was not precisely at

90 degrees to the bushing in the dampener.

Track bar

Removing the track bar was not difficult. Re-installing it did

require pulling the axle toward the driver side of the vehicle,

which we accomplished by way of a ratcheting tie-down strap.

Removing the factory bushing was straightforward with the ball joint

press, and the polyurethane replacement bushing can be inserted by

hand.

Wheel hubs and brakes

With the steering knuckles and linkage back in place, the wheel hubs

could be re-installed. As previously mentioned, I had to replace

both hubs. I elected to clean and paint the shields that mount

behind the hubs to protect the back side of the brake rotors before

re-installing the hubs over them, as well. Bolting the hubs on was

as easy as taking them off, with the most difficult part being

putting 175 ft-lbs on the axle nut.

At this point, it did become obvious that the grease zerks supplied

with the lower ball joints are unusable. They were tall 45 degree

affairs that interfered with the U-joint. The passenger side

sheared without any commotion (I didn’t even notice), but the driver

side stopped the wheel from rotating and I briefly thought there was

a problem in the half-axle or differential. Once the offending zerk

was located and both sides were replaced with simple caps, the

problem went away.

Control arms

In order to keep the axle in place as much as possible, I elected to

replace the control arms one at a time. Because I was replacing the

arms along with the bushings, I didn’t have to push out the lower

arm bushings or the upper arm frame bushings, and the new arms came

with these bushings pre-installed. Removing and replacing each

lower control arm in turn was straightforward, although re-installing

the bolts required jacking up the axle on the installation side and

pulling it to the rear with a ratcheting tie-down.

Removing each upper control arm was similarly straightforward.

Removing and replacing the upper control arm bushings (specifically

the driver side upper control arm axle bushing) was the most

difficult part of the whole job. This was due to a combination of

the unsuitability of the ball joint press for the job and the

difficulty of reaching the driver side ball joint due to interfering

parts (such as the coil spring, pitman arm, and drag link; in

retrospect, replacing this bushing before installing the steering

linkage would have been somewhat easier). The passenger side

bushing was easier than the driver side bushing due to the

construction and geometry of its bracket (it’s a U-shaped sheet

metal bracket, versus the driver side bracket which is cast into the

differential housing, and the bushing presses almost all the way

through it, allowing the control arm to be used for final seating).

However, I did bend the bushing bracket slightly removing the

bushing; I’m not sure how one would press it out without doing so,

actually. It did not bend far, and straightening it was not

difficult, and I do not believe it to be worse for the wear.

The passenger side bushing was pushed back in with a combination of

the ball joint press to get it started and the control arm itself

with large washers and some light blows against the bracket to do

final seating. I wouldn’t recommend this method, necessarily, but

it worked and it was easier than the other side.

The driver side bushing couldn’t be pushed out because there was no

way to get the press on it square enough to move it substantially.

Removing it was therefore a combination of burning the rubber (with

a propane torch), pushing out the center metal bushing, then

cutting, crushing, pulling, twisting, and otherwise brutalizing the

outer metal shell until it came free. This was the single most time

consuming task of the entire job; it took approximately two and a

half hours. Re-installing it likewise could not be done with the

press, so we employed the press receiving rings, a large socket, a

number of washers and nuts, and a long piece of threaded rod to

press it into place. Getting it started square with the hole was

tricky (for one thing, the hole in the bracket appears to be neither

square with the ground nor parallel to the front-back axis of the

vehicle), but by witnessing it both from the front through the

steering linkage and from the top past the steering fluid reservoir

and employing judicious blows from the 3 lbs hammer (another

two-person job), we got it started. Once it was started, it was

simply a matter of cranking down on the threaded rod until it broke

(we could get neither grade 5 nor grade 8 rod on short notice) and

then finding a fresh part of the rod where the nuts would thread on

and starting again. All told, it was much easier than removal, but

still time-consuming.

I found that re-installing the upper control arms was easier if the

axle end bolt was pushed in first, as the front of the control arm itself

has more play in it than the rear (as the rear has a bushing pressed

into it holding it rigid, while the front is a loose U until

bolted in), allowing the rear bolt to be jimmied into place by

bearing on the control arm. I believe the driver side upper control

arm also required some ratchet strap treatment, although I do not

fully recall.

Final assembly and alignment

With the steering linkage assembled and the control arms replaced,

the tires can be remounted and the Jeep set back on the ground. I

tightened the sway bar bushing bolts after setting it back down,

then checked the various fasteners that do not have a cotter pin

(sway bar links, control arms, steering dampener, etc.).

I had alignment done by a professional shop. The driver’s side

wheel was not toed in quite far enough, but other than that

everything checked out. Getting to the alignment shop was not an

issue. Measuring the tie rod ends and reproducing those

measurements worked great; my suspicion is that the remaining

alignment problems were from the previous alignment correcting for

destroyed lower ball joints (as it was last aligned after the Death

Wobble had taken hold). Measurement error is of course also a

possibility.

Lessons learned

It took about four days for this job. I started on Friday afternoon

and finished late on Monday, skipping only Saturday morning due to

other commitments. I think if we did it again this coming weekend,

it would take about two days. It’s a big job no matter how you

slice it, and it’s going to be a lot easier with two people; in

particular, getting the ball joints and upper control arm bushings

pressed in will be easier with an extra pair of hands. Most of the

other operations can be done solo with a minimum amount of

difficulty, but not having someone to “hold the other

end” or hand you tools will slow you down.

The biggest non-equipment lesson taken out of this is order of

operations. I wanted to get the steering linkage completely in

place before doing the control arms in order to minimize the

possibility of anything coming too far out of alignment, but in

retrospect it would have been much easier to deal with the upper

control arm bushings (particularly on the driver side) with the

steering linkage removed. I don’t think there’s any reason not to

do this. The steering linkages are all flexible anyway, and the

track bar and remaining control arms (assuming they’re replaced one

at a time) will keep things where they belong.

As far as equipment, I had seen several comments that the typical

ball joint press that can be rented at local auto shops doesn’t

really have the right fittings for a TJ Wrangler. There are kits

available to adapt those presses for Jeeps, and there are presses

for Jeeps. They are relatively expensive; I am not sure I would

purchase one, but I might call around to local shops and see if I

could find one to rent. The shop I rented the press

from did have adapter kits for some vehicles (mostly

imports), but not Jeeps.

Total costs

The total costs were as follows:

| Description | Qty. | Price | Total |

|---|

| Track Bar | 1 | 65.77 | 65.77 |

| Drag Link Kit | 1 | 100.00 | 100.00 |

| Steering Stabilizer | 1 | 54.14 | 54.14 |

| Sway Bar Link Kit | 1 | 55.38 | 55.38 |

| Sway Bar Bushing Set | 1 | 24.99 | 24.99 |

| Track Bar Bushing | 1 | 9.99 | 19.98 |

| Front Upper Control Arm Axle Bushing | 2 | 11.85 | 23.70 |

| Front Upper Control Arm | 2 | 29.99 | 59.98 |

| Front Lower Control Arm | 2 | 34.99 | 69.98 |

| Ball Joint Kit | 2 | 44.29 | 88.58 |

| Right Tie Rod End | 1 | 23.99 | 23.99 |

| Left Tie Rod End | 1 | 31.99 | 31.99 |

| Front Wheel Hub | 2 | 63.99 | 127.98 |

| Alignment | 1 | 79.99 | 79.99 |

| Total: | 826.45 |

Several of these parts are available cheaper, but I wound up paying

more either to get them in time or to consolidate orders, or because

I didn’t trust some sources (e.g., the entire steering linkage is

available for just a few dollars more than I paid for the drag link

… and possibly made of cheese?). In particular, I bought the

tie rod ends locally, which cost me about $20 more than ordering

them with the majority of the rest of the parts, but Quadratec

didn’t have them in stock.

While I did preorder most of the parts without knowing if they were

absolutely required, when all is said and done I don’t think I

replaced a lot of things that didn’t need to be replaced. The upper

ball joints may have been OK, as may have been the control arms

themselves (but the bushing rubber wasn’t in great shape). However,

I don’t think I would change the lower ball joints without the

upper, and the upper control arms were sold as a unit with the rear

bushings; I might have been able to save $30 or so by buying lower

control arm bushings instead of lower control arms. I could of

course have aligned everything myself, but I was more comfortable

leaving that to a professional. I don’t think I could have reduced

the above cost by more than about $100 in practicality, except maybe

by vetting some of the cheaper parts suppliers for legitimacy and

ordering from multiple sources.

Results

So far, it seems to have worked. I’ve driven several problem roads

with nary a Wobble, and no pre-Wobble vibrations. The steering is

much stiffer and more responsive; I attribute this to three

things: 1) the old parts were worn, 2) the new

parts haven’t yet broken in, and 3) replacing rubber

bushings with polyurethane in several places. All in all I like the

feel much better than what I’d grown used to!

Acknowledgments

I had a lot of help on this one. One friend spent about 2 1/2

of the four days here working in my driveway, and my dad dispensed a

fair amount of advice over the phone (he has an XJ, which has a very

similar front end).